MOB:0086-13962254616 | Email: sales@fillingmachinegroup.com

| Availability: | |

|---|---|

| Quantity: | |

CXGF16-16-6

JDY

84223010

Our factory started production the machine in 2013, there are more than 100 sets bottling machines sold around whole the world each year. All the customers report that they are very good, simple to operate, and the bottling machines are running smoothly.

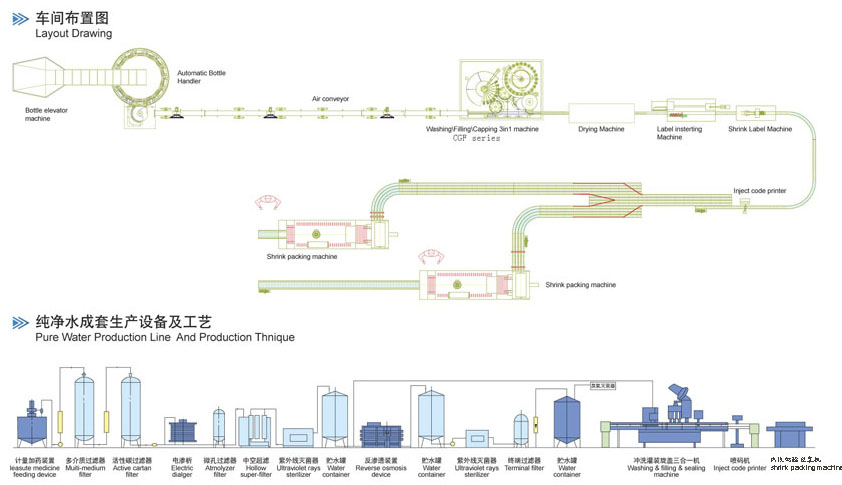

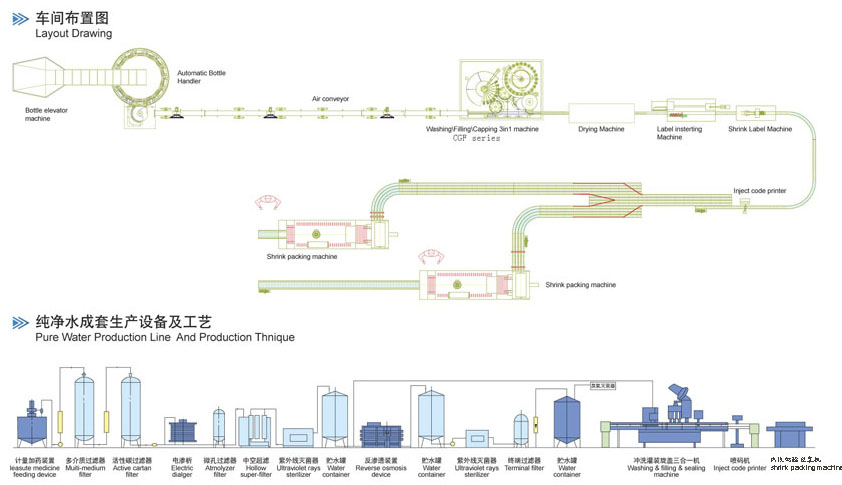

The water filling packing machine is used in production of PET bottling-packing water such as pure water, mineral water with the capacity from 3000-20000B/H, the filling machine is featured by scientific and reasonable design, beautiful appearance. Complete functions, convenient operation and maintenance and highly automatic. The bottling filling packing machine is the best choice for small and medium-sized beverage manufacturers.

Our factory started production the machine in 2013, there are more than 100 sets bottling machines sold around whole the world each year. All the customers report that they are very good, simple to operate, and the bottling machines are running smoothly.

The machine washing,filling,capping parts can be realized in one machine, the monoblock filling machine unit is featured by scientific and reasonable design, beautiful appearance. Complete functions, convenient operation and maintenance and highly automatic. Bottling machine is combines advanced technology from Italy and Germany. Its filling speed high and liquid control is stable. The bottling machine adopts empty bottle air conveying . bottle mouth clamping, rinsing, filling and capping that not restricted by the height of the bottles. Different shapes of bottles can be changed freely only keep the bottle mouth and cap are the same. When bottling machine changing the bottles, just change the bottle feeding plate.

The bottling machine driven by the oil nylon gear with low noise and stable running. The magnetic torque type cap screwing head is adopted the cap grabbing and cap screwing. The cap screwing torque adopts step-less adjustment. Bottling machine has the constant torque cap screwing and capping function, and it will not damage the cap and the sealing is tight and reliable. The horizontally rotary cap handler has such functions as no damage to the cap surface, signal sending and automatic cap filling in case of cap shortage of the hopper. The bottling machine adopts the PLC control which is the man-machine interface touch screen control. Bottling machine provided with such functions as automatic control of the liquid level in the material cylinder, no bottle no filling and no bottle no cap feeding. The bottling machine will stop when the bottle blocking or dislocation by the bottle feeding star wheel and cap shortage in the cap groove.

Product Description

1) Compact structure, good shape, easy operation, high automation degree and low labor intensity.

2) Adopts the technology of direct contact air conveyor and bottle inlet poking wheel, instead of " Feeding screw" And " Conveyor" ; Thus making it is easy to change the bottle shape.

3) Adopts bottle neck clamping technology which removes the need for changing the height of the bottle; Just change the parts which are relevant to the bottle diameter, such as the arc guide plate and poking wheel.

4) Special stainless steel bottle gripper of rinser does not touch the bottle screw part, thereby avoiding secondary contamination.

5) All parts directly contacting the media adopt food stage stainless steel, without dead angles, so they can be cleaned easily.

6) Diaphragm adjustment valve controls the inlet flow rate of liquids, and can keep the slight turbulence of liquids level in the solution barrel and ensure accuracy in filling.

7) Automatically closes feeding valve if there is no bottle on the machine, thus avoiding the loss of aqueous feed.

8) Fills automatically with high speed and accurate control of liquid level.

9) High filling speed and mass flow rate, high precision of filling valve and control of liquids level is accurate and without loss.

10) Equipped with perfect CIP control loop and program and cleaning devices on the spot.

11) The "Capping head" Adopts a magnetic constant-torque device to ensure high capping quality without damage.

12) Adopts efficient cap settling system with perfect cap feeding and protection device.

13) Adopts spiral descent fashion for the support plate for bottom of bottle at the outlet thumb wheel, which removes the need for adjusting the input height for exchanging bottle models.

14) Equipped with perfect protection system to prevent overload, and protect facilities and operators efficiently.

15) Applying touch screen, it fully realizes the man-machine conversation whereas the status of device running is clear at a glance.

16) The primary electric components such as touch screen, PLC and transducer all adopt well known import products.

Main Parameter:

Model: | CXGF14/12/5 | CXGF16/16/6 | CXGF18/18/6 | CXGF24/24/8 | CXGF32/32/10 | CXGF40/40/10 |

Capacity: 500ml(b/h) | 4000 | 6000 | 8000 | 10000 | 15000 | 18000 |

Suitable Bottle: | 150-340(mm) | |||||

Suitable Cap: | φ50-φ110 (mm) | |||||

Filling Pressure: | 0.2-0.3(Mpa) | |||||

Power (kw) | ||||||

Size : (mm) | 2400×1670×2350 | 2470×1970×2350 | 2865×2170×2350 | 3200×2170×2250 | 3800×2950×2400 | 4500×3400×2400 |

Weight:(kg) | 2500 | 3000 | 4000 | 5000 | 6000 | 8000 |

Our factory started production the machine in 2013, there are more than 100 sets bottling machines sold around whole the world each year. All the customers report that they are very good, simple to operate, and the bottling machines are running smoothly.

The water filling packing machine is used in production of PET bottling-packing water such as pure water, mineral water with the capacity from 3000-20000B/H, the filling machine is featured by scientific and reasonable design, beautiful appearance. Complete functions, convenient operation and maintenance and highly automatic. The bottling filling packing machine is the best choice for small and medium-sized beverage manufacturers.

Our factory started production the machine in 2013, there are more than 100 sets bottling machines sold around whole the world each year. All the customers report that they are very good, simple to operate, and the bottling machines are running smoothly.

The machine washing,filling,capping parts can be realized in one machine, the monoblock filling machine unit is featured by scientific and reasonable design, beautiful appearance. Complete functions, convenient operation and maintenance and highly automatic. Bottling machine is combines advanced technology from Italy and Germany. Its filling speed high and liquid control is stable. The bottling machine adopts empty bottle air conveying . bottle mouth clamping, rinsing, filling and capping that not restricted by the height of the bottles. Different shapes of bottles can be changed freely only keep the bottle mouth and cap are the same. When bottling machine changing the bottles, just change the bottle feeding plate.

The bottling machine driven by the oil nylon gear with low noise and stable running. The magnetic torque type cap screwing head is adopted the cap grabbing and cap screwing. The cap screwing torque adopts step-less adjustment. Bottling machine has the constant torque cap screwing and capping function, and it will not damage the cap and the sealing is tight and reliable. The horizontally rotary cap handler has such functions as no damage to the cap surface, signal sending and automatic cap filling in case of cap shortage of the hopper. The bottling machine adopts the PLC control which is the man-machine interface touch screen control. Bottling machine provided with such functions as automatic control of the liquid level in the material cylinder, no bottle no filling and no bottle no cap feeding. The bottling machine will stop when the bottle blocking or dislocation by the bottle feeding star wheel and cap shortage in the cap groove.

Product Description

1) Compact structure, good shape, easy operation, high automation degree and low labor intensity.

2) Adopts the technology of direct contact air conveyor and bottle inlet poking wheel, instead of " Feeding screw" And " Conveyor" ; Thus making it is easy to change the bottle shape.

3) Adopts bottle neck clamping technology which removes the need for changing the height of the bottle; Just change the parts which are relevant to the bottle diameter, such as the arc guide plate and poking wheel.

4) Special stainless steel bottle gripper of rinser does not touch the bottle screw part, thereby avoiding secondary contamination.

5) All parts directly contacting the media adopt food stage stainless steel, without dead angles, so they can be cleaned easily.

6) Diaphragm adjustment valve controls the inlet flow rate of liquids, and can keep the slight turbulence of liquids level in the solution barrel and ensure accuracy in filling.

7) Automatically closes feeding valve if there is no bottle on the machine, thus avoiding the loss of aqueous feed.

8) Fills automatically with high speed and accurate control of liquid level.

9) High filling speed and mass flow rate, high precision of filling valve and control of liquids level is accurate and without loss.

10) Equipped with perfect CIP control loop and program and cleaning devices on the spot.

11) The "Capping head" Adopts a magnetic constant-torque device to ensure high capping quality without damage.

12) Adopts efficient cap settling system with perfect cap feeding and protection device.

13) Adopts spiral descent fashion for the support plate for bottom of bottle at the outlet thumb wheel, which removes the need for adjusting the input height for exchanging bottle models.

14) Equipped with perfect protection system to prevent overload, and protect facilities and operators efficiently.

15) Applying touch screen, it fully realizes the man-machine conversation whereas the status of device running is clear at a glance.

16) The primary electric components such as touch screen, PLC and transducer all adopt well known import products.

Main Parameter:

Model: | CXGF14/12/5 | CXGF16/16/6 | CXGF18/18/6 | CXGF24/24/8 | CXGF32/32/10 | CXGF40/40/10 |

Capacity: 500ml(b/h) | 4000 | 6000 | 8000 | 10000 | 15000 | 18000 |

Suitable Bottle: | 150-340(mm) | |||||

Suitable Cap: | φ50-φ110 (mm) | |||||

Filling Pressure: | 0.2-0.3(Mpa) | |||||

Power (kw) | ||||||

Size : (mm) | 2400×1670×2350 | 2470×1970×2350 | 2865×2170×2350 | 3200×2170×2250 | 3800×2950×2400 | 4500×3400×2400 |

Weight:(kg) | 2500 | 3000 | 4000 | 5000 | 6000 | 8000 |

MOB:0086-13962254616

Email: sales@fillingmachinegroup.com

whatsapp:008613962254616 always online!